Mounting systems for free-standing systems

The solution for a free-standing PV offers maximum flexibility, as it is available in both rammed and anchored versions. Some of the system components are pre-mounted in the factory, which reduces installation work. Thanks to flexibly designed perforations in the montage profiles, the systems allow almost any mounting option to become reality – and not only using the OBO terminals provided for this purpose, but also using conventional fastening materials, such as standard bolts.

Product highlights

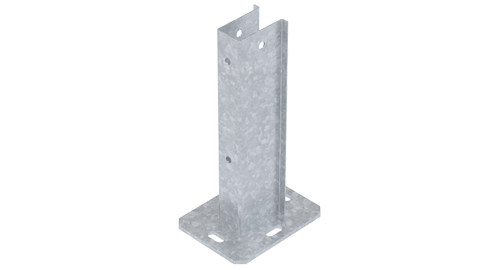

Stand for concrete foundation

- Anchored version for concrete substrates, for example

- Stable connection technology, e.g. through the use of wedge anchors

- The pre-mounted supports are mounted with easy-to-use screw fastenings

Ramming pile for pre-mounted supports

- Rammed version for green areas, for example

- The pre-mounted supports are mounted with easy-to-use screw fastenings

- 2 variants available, depending on the ramming depth

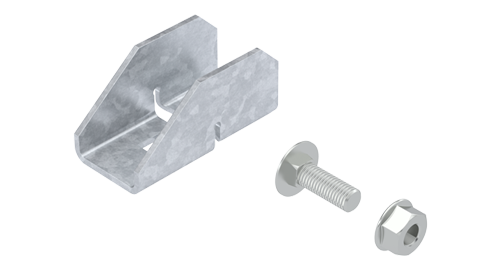

Cross-connector for support profiles

- Highly secure fastening of the support profiles on the pre-mounted supports

- The above components are attached using the simple fastening screw provided

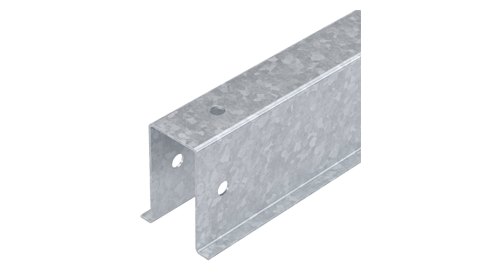

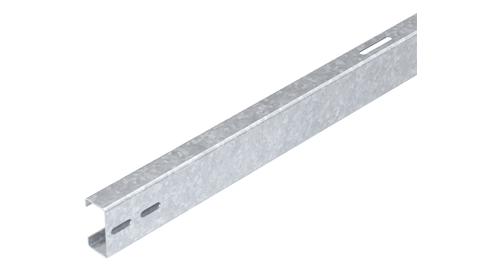

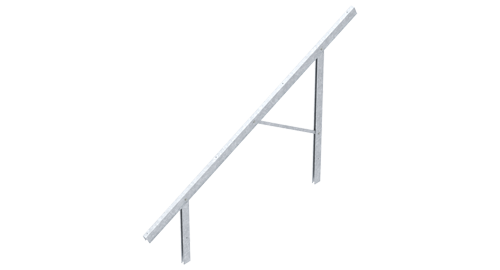

Support profile for free-standing system

- Mounting profiles with flexible lengths and perforations offer numerous possible mounting options, for example using simple standard bolts

- Many different variants available, depending on the size of the PV modules used

Pre-mounted support for free-standing systems

- System components pre-mounted at the factory reduce the amount of installation work required on site

- Supports are unfolded on-site, attached to the anchored or rammed pile and fixed in place using the appropriate fastening material

- Cross-bracing provides additional support for the entire system

- Many different variants available, depending on the tilt angle and size of the PV modules used

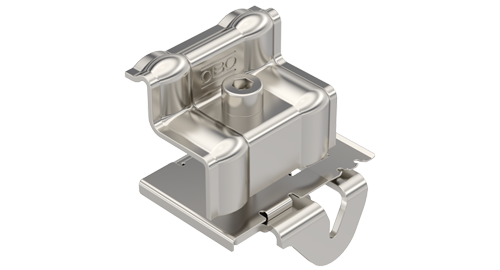

End clamp for free-standing systems

- The PV module is fixed using a pre-mounted fastening screw

- Many different variants available, depending on the frame height of the PV modules used

- In addition to end clamps, the OBO product range also includes corresponding intermediate clamps

- Long service life thanks to the use of high-quality stainless steel